Description

Braille Paper Continuous Feed Sheets - 11.5"×11"

Top quality 11.5×11" – Plain Cut Sheet (Single Sheet) Braille Paper that is recognized and used worldwide by government agencies, educators, transcribers, individuals and many more.

Why choose ATC for your braille paper needs?

American Thermoform Corporation has produced Braille paper since 1988. We are the only manufacturer of braille paper who is actually in the braille business. We teamed up with paper specialists and developed a paper made specifically for us, to be used in today’s standard continuous form braille embossers. ATC is the largest distributor of production braille embossers in North America and we know exactly what type of paper works best. Using the wrong paper and “odd-lots,” which many of our competitors use, can cause serious damage to your braille embosser. Additionally, our paper is created at a single mill, ensuring consistency in color and texture from order to order.

What are the standard formats?

American Thermoform Corporation offers braille paper in three different formats – continuous (tractor feed/fanfold), cut sheet and rolls.

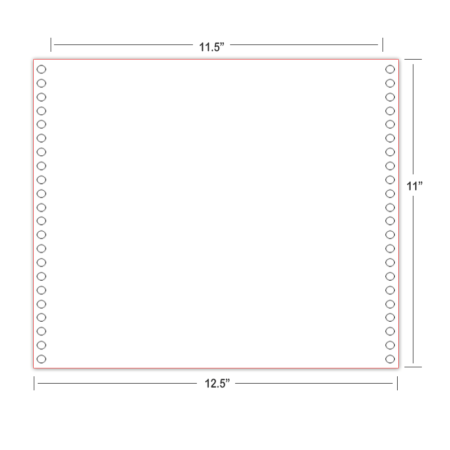

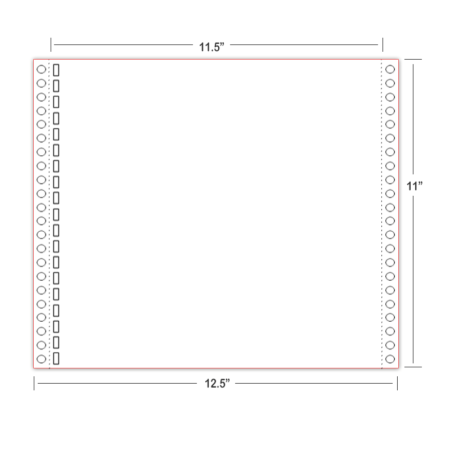

Continuous

The standard U.S. finished Braille paper sizes (once you tear off the tractor feed edges) are 8.5×11” and 11×11.5”. We offer all sizes in plain, 19 hole or spiral pre-punched formats. The 19 holes and spirals are punched on the left hand side and are to be used with standard binding rings. Should you need special sizing (index cards, calendars, European, etc.) we are able to produce it in-house with extremely fast turn-around times.

Cut Sheet

We carry cut sheet braille paper in 8.5×11”, 11×11.5″, A4 or any custom size and format that you may need. Please contact us for special cut sheet sizes and formats.

Rolls

We ship our braille paper rolls across the world and can accommodate whichever size your machine requires. Standard roll sizes have a width of 8.5″, 9.5”, 11.5″ and 12.5”. Should you need a different size, please contact us and we will gladly make it for you.

Top things to consider when purchasing Braille paper:

Quality of the paper. We offer an acid free and dust free paper, which is manufactured from a single mill. By doing so, we are able to offer the finest quality and consistent paper available.

Weight of the paper. Paper that is too thin will cause holes in your braille dots when Brailled. If the paper is too thick, it could damage your embosser. ATC uses an ideal paper weight that has been specially designed and formulated for us.

The finished product. It is important to have clean tractor feed holes to prevent problems going through the embosser, as well as clean perforated edges for sheeting purposes. The holes on our 19 Hole and spiral format are completely punched out to ensure proper binding. Lastly, ATC has strict paper packaging guidelines to prevent folding and damage during shipment.